Oil Filter

Today we keep our cars for longer periods of time so the proper maintenance of the engine is of a great importance. The engine of automobile consists of many metal parts that are being rubbed together. If you keep it running like that with time this will heat the engine up and it will not function properly. To avoid that we add engine oil to decrease the rubbing. However, dirt and metal pieces pollute the oil as well as the engine. This leads us to oil filter that will keep your engine running for much longer. Regular change of this filter is a must for a proper engine operation. Hence, picking the right filter for your car is very important.

We can assist you in finding the right filter in our online shop filkit.com.ua.

Oil filter is designed to extract pollution from engine and transmission oils as well as hydraulic liquids.

In 1923 first oil filter for automobile was proposed by Ernest Sweetland and George H. Greenhalgh. This filter, however, let most of the fluid to get in to engine and filtered only small amount of it. Twenty years after new filter was developed that filtered all the oil before it reached the engine. However, for a flawless job it required the oil volume and pressure not to exceed certain number.

Functions

Engine oil and oil filter have a few more functions besides lubrication:

- cooling (absorption and transfer of high temperature from the friction and combustion areas);

- purification (transfer (to the filter) of polluting particles that are formed during wear as well as residues from the combustion process);

- sealing (of rings between the sleeve and the piston, gaskets, seals, etc. reduction of noise: both mechanical and from the combustion process).

While the contaminating particles are not sufficiently removed from the engine oil and are caught by an oil filter, they can form an abrasive paste together with the oil that causes premature wear of the engine. This will lead to high repair costs.

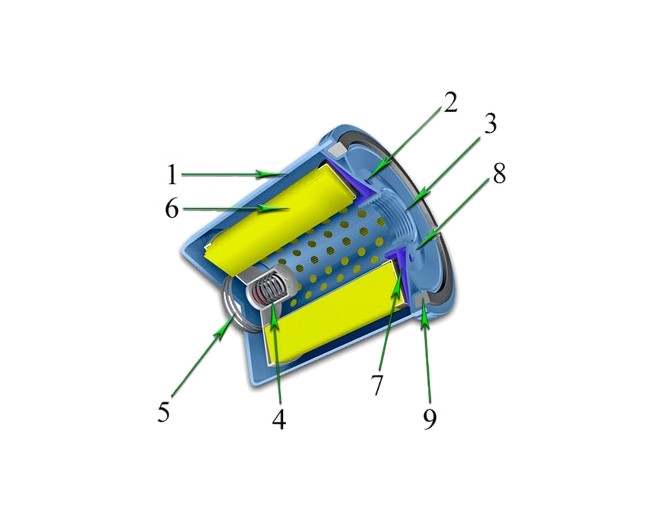

The inside of oil filter

• The housing (1) allows you to maintain the integrity of all internal elements of the oil filter.

• The openings are intended for the input (2) and the output (3) of the oil in the filter. Small holes along the edges serve for free movement of oil into the container. The filter is attached to the engine with a threaded hole in the center that oil flows through.

• The drain valve (4) overlies the large hole for the screw. All the oil can merge back into the filter in the off mode since the oil filter is located inside or in the bottom of the engine. An anti-drain valve that has a rubber cover prevents it.

• The spring (5) works together with the drain valve. It presses on the valve so that in the idle mode of the engine the oil does not leak away. More often now a lamellar spring is being used which takes up less space.

• Filter material (6) has a lot of small pores and consists mainly of microscopic fibers of cellulose and synthetic materials. Glass and polyester is also being used. It increases the efficiency and durability of filtration. In some cases, the material is saturated with a resin that gives it that extra rigidity and strength. The folders have most of filters. This arrangement of material allows to increase the total area of its surface.

• The safety valve (7) is located on the other side of the filter, in front of the threaded hole. In some cases, pressure inside may increase and as a result some internal filter elements may be damaged. When this happens the safety valve opens to stabilize the pressure.

• The filter lid (8) provides airtightness.

• The sealing ring (9) provides tightness.

Material of the filter element of oil filters

Filter material consists of cellulose fibers, which is commonly referred to as "paper filter". Cellulose is soaked with resins in such a manner that a structure with high porosity is formed. However, cellulose was replaced by synthetic fibers with even smaller pores. This was achieved using a multi-layer structure with a different density of pores. Filter materials of mixed type, made from a combination of cellulose and synthetic fibers recently become widely used. In any case, each type of material is detaining foreign solid particles. Synthetic fibers not only demonstrated increased resistance to contaminants, but also improved the mechanical strength of the filter.

Filter material consists of cellulose fibers, which is commonly referred to as "paper filter". Cellulose is soaked with resins in such a manner that a structure with high porosity is formed. However, cellulose was replaced by synthetic fibers with even smaller pores. This was achieved using a multi-layer structure with a different density of pores. Filter materials of mixed type, made from a combination of cellulose and synthetic fibers recently become widely used. In any case, each type of material is detaining foreign solid particles. Synthetic fibers not only demonstrated increased resistance to contaminants, but also improved the mechanical strength of the filter.

Why a filter has a shape of fluted canister?

In order to have the largest active surface, while maintaining compact dimensions, the filter element is being folded into "harmonica" (pleated). The hydrodynamic shape of such a surface reduces the resistance of the oil flow. In an unpolluted, high-quality filter, the difference in pressure at the inlet and outlet should have acceptable values - about 0.5 bar or less. The plaster increases the service life of the filter material. Due to the increase in the accumulation area, the filter can hold a larger number of foreign particles before the flow resistance becomes excessive.

It is necessary for the oil filter to be equipped with a bypass (emergency) valve, which opens in the event of the filter element not being able to pass through the flow of oil. Thus, the oil enters the engine without undergoing cleaning.

This can happen for several reasons:

a) if the filter element is dirty (it has accumulated too many foreign particles);

b) if the oil is still too viscous after the cold start of the engine;

c) if the filter element is made from very dense material.

Typically, the bypass valve is calibrated at a pressure of 1-2.5 bar. Due to the technology of double folds such as "chevron" it is possible to further increase the surface area which filters while preserving the external dimensions.

Based on online resources

Leave a Reply Cancel Reply

All fields are required