Automobile engine requires fresh air just as any person. The combustible mixture burns completely if it contains oxygen, the content of which has 15-20 times the amount of fuel. Uncleaned air pollutes the engine that leads to its irrational work and breakage. The air filter, hence, corresponds to the access of clean air inside the engine.

For optimal engine operation, a certain amount of air is required. On average, 15 kg of air goes on burning 1 liter of gasoline. In addition, the quality of this air should be high enough: a certain temperature, density, oxygen saturation and purity. Even microscopic dust particles can lead to the rapid wear of finely fitted parts.

The most dangerous types of air pollution are:

- sand (undiluted sandstones rub metal surfaces like emery, causing them to become completely unsuitable);

- water (water vapor, when getting into the block of cylinders, causes rust, which has powerful abrasive properties);

- dust, soot from the road and flower pollen also affect the car.

The task of the engine air filter is the most effective cleaning of air that enters the internal combustion engine. In addition, it also performs few more functions:

- reduces the noise level that extends through the valve;

- adjusts the temperature of the fuel (only in the petrol cars);

- regulates the uniformity of the air flow;

- prevents moisture from entering.

Under normal operating conditions, the air filter reduces engine wear by 15-20%, and in difficult conditions - by 200%.

The air filter is located under the hood in a special case. It receives air through the air supply that passes it through the filter element and then goes on to the air flow meter and ends up in the combustion chamber. The placement and method of fastening allows you to change the air filter in minutes in the shop or on your own.

The main purpose of the air filter is to clean the air from the contaminants before it enters the engine. The filter element absorbs large and small particles of dust, providing free access of oxygen to the engine. The air filter cleans the atmospheric air involved as an oxidizer in the working mixture that burns out in the cylinders of the internal combustion engine.

Types and features

All modern passenger cars are equipped with paper air filters of various configurations. They surpassed oil-inertia and coal filters by the quality of filtration, reliability and dimensions.

Air filter manufacturers are developing new materials that improve the performance and quality of the filtering. There are over 400 types of paper used by different firms. The most common material is corrugated cardboard. It perfectly detains all the dirt and does not allow it to spread on the engine. However, some manufacturers use special synthetic fibers as absorbent material, stronger and more durable than paper, which perform their functions better.

To allow the filter to retain water, without losing its properties, the paper is satiated with different contents of the resins, due to which the filter remains efficient even at high humidity, at the action of microscopic droplets of gasoline, machine oil, antifreeze and other aggressive chemistry.

In order to prolong the service life, the technology of deep filtration (a three-layer paper structure, the pores being reduced from the surface to the middle) are used. Larger particles are retained by surface layers and small ones are retained by deep layers, and almost perfectly clean air of the required temperature passes through the filter. The use of surface filtration - on the principle of a simple grid - would lead to an instant clogging of the filter.

To increase the area of contact between the filter cloth and air, the material is folded in the form of "accordion". The shape of the filter element depends on the body that is mounted on the engine.

According to the form, air filters are distinguished as:

Circular (ring) - old sample filters (installed on a car with a carburettor system). Such filters are often provided with an aluminum mesh frame to increase durability. However, the main drawback of ring filters is their insufficient area of filtration, despite the fact that they occupy a lot of space.

Panel (frame and frameless) - the most common filters (installed in injector and diesel cars). They can be reinforced with metal or plastic mesh, which reduces vibration and deformation of the filter material. They are characterized by compactness, durability, a fairly large area of filtration and ease of use.

Cylindrical - occupy less space than a ring, but have a large surface area (installed on commercial vehicles with diesel engines, as well as some models of passenger cars).

Number of stages of filtration:

One-stage (the filter consists only of filter paper, folded in "accordion". The simplest option, in which all loads are on the filtering element).

Two-stage (a pre-filter, installed in front of a paper filter, is a synthetic material that holds up large particles. It is used for severe operating conditions: in dusty air, with frequent trips off-roads).

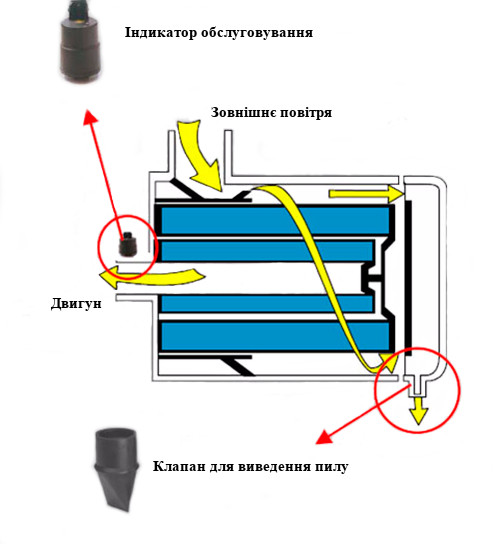

Three-stage (before air reaches the filter it is pre-cleaned by cyclone rotation. Solid particles along with the air flow lose energy and settle in the filter housing or in a special container, either by the design of the filter housing or by a special impeller in the filter itself, which gives the direction of air flow)

The adjacent places of the insert filter are made of rubber, which prevents the untreated air from entering the combustion chamber.

Requirements for air filters

The main requirement for the filter is to ensure the maximum removal of foreign impurities from the air entering the engine. It is possible to achieve qualitative filtration by increasing the density of the filter element (the denser the paper, the more dirt it will hold). But any filtering element holds back the air needed to operate the engine, so increasing the density of the filter has its limits. As the filter contributes to increasing its resistance, it means that the throughput decreases.

In addition to the requirements for the quality of filtration, there are also consumer requirements:

- normal operation during the entire life exploitation;

- exact conformity to the required overall dimensions,

- the quality of the assembly, which ensures the serviceability of the filter for the entire period of work.

Operation of the air filter

Proper operation reduces to the purchase of a good filter, correct installation, tracking of the state visually or by the sensor of pollution and timely replacement. The air filter does not require any special attention.

The replacement is carried out according to the regulations specified in the service book. Given the fact that for each car there are filters assigned with certain parameters, you can not exceed the term of replacement: by this time the filter will be a tangle of dirt, leaves and insects.

The shortening of the replacement period is possible under difficult operating conditions:

- use of the car in a very dusty area,

- spring-summer season, when there are many insects and pollen of plants,

- frequent riding on the sand,

- building (cement) dust,

- city smog.

Also, the duration of operation is influenced by the location of the air intakes; the most advantageous is near the exhaust pipe. In this case, the filter will get a heated air (and therefore less dense and with less oxygen), as well as soot and steam of unburnt fuel.

The length of its operation depends on the area of the filter (the higher the air flow - the greater the surface area of the filter should be). When additional equipment is installed on the engine (turbocharger system), more air will pass through the filter which means that more dirt will be detained by the filter element.

On the average, the replacement of the air filter is carried out at the same time as every other replacement of the engine oil, and with the reduced replacement regulations - twice as often.

Compliance with the air filter replacement mode has its undeniable advantages:

- you do not have to worry about the supply of air: in normal operation, the filter fully operates the entire term;

- optimum fuel consumption;

- less wear of the engine parts;

- less pollution of fuel injectors;

- less repairs.

You can replace the filter either on your own or at the shop during maintenance.

When replacing yourself, you need to pay attention to several points:

- you have to be careful when getting the old filter so that the dust does not get into the exhaust manifold, otherwise it will go straight into the engine),

- the lid of the housing should be tightly closed, to all latches and screws (so that air from the atmosphere does not pump in the cracks bypassing the filter).

Based on internet resources

Leave a Reply Cancel Reply

All fields are required